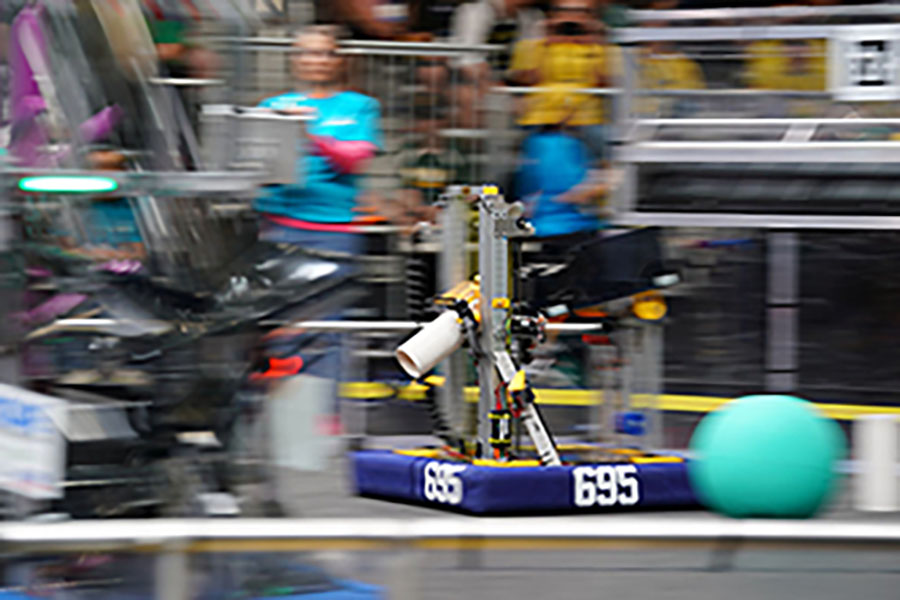

After months of dedication, design, and development, the robotics team 695, which consists of approximately 80 percent BHS students, earned a coveted spot at the FIRST Robotics World Championship in Houston, Texas on April 19.

While the team did not make it as far as they had hoped in the global competition due to a mechanical error during their division playoff round, they still managed to place in the top 100 teams out of approximately 3,500, and placed second in Ohio.

Every year, teams around the country are required to build robots that complete a new challenge; teams are scored on the time it takes to successfully complete the assigned task.

As the year goes on, teams tweak everything–strategy, design, material and programming.

“We have a couple of subteams: design, software, strategy, and I’m on fabrication,” said sophomore Asher Hardis, member of Team 695. “Fabrication does the actual building of the robot. At competitions, we’re in the pits…if something breaks, we fix it.”

The stakes are always high, but especially at the global competition. Teams compete in preliminary rounds before a final bracket. However, what separates the good teams from the great teams usually isn’t the robot–it’s the strategy.

“At globals, the score records got broken ten or fifteen times,” Hardis said. “Teams get their strategies figured out; they figure out the best way to score the most points by the end of the year.”

The most impressive feature of 695’s robot this year, Goldfish, is its alignment software. Equipped with dual cameras, Goldfish could estimate its location and almost entirely automatically align itself for scoring.

“A lot of teams have that kind of technology, but ours is unique because our software team wrote it from scratch,” Hardis explained. “We automated almost everything, alignment for intake, alignment for scoring [and more].”

That level of innovation shows just how much the team has evolved. As the team has grown from six to over thirty-five members in the last three years, team dynamics have changed drastically.

Moreover, the number of women in the club has tripled from two to six in the last two years. Head coach Sean Keyerleber agrees that the increase in membership has helped the team evolve.

“We don’t really think of [recruiting girls or boys] necessarily,” Keyeleber said. “It just happens because [we] treat everybody as a contributor.”

“It’s been exciting to see,” he added. “We now have half a dozen women on the team, and they’ve been great this year.”

Keyerleber, who’s coached Team 695 since 2017, said the club has become more student-led over time.

“The mentors and I are there to facilitate,” he said. “We’re the enablers to make the team happen, but it’s really on the students to dig in and figure out, ‘how far can we take this?’,” he explained.

Evidently, that strategy worked. Team 695 also became Buckeye Regional Champions in early April at Cleveland State University.

“To win, there’s three things that have to happen,” Keyerleber said. “You need a good design…a durable design…and a little bit of luck.”

However, funding could prove to be another challenge. Each student had to pay around $1,000 out of pocket for transportation, hotel and meals to go to Houston.

“There is a cost to this,” Keyerleber said. “$1,000 for a student to go to Houston. Luckily we had 20-25 students make the trip, which is fantastic but costly.”

To help cover the cost, the team is launching a fundraising committee.

“We have a couple people putting together… [information for solicitations],” he said. “We’ve actually gotten a couple of contributions from community donors.”

According to team member Ben Keyerleber, the team has received funding from the Beachwood Board of Education and sponsorship from Fabworks laser sheet metal cutting service.

The team plans to ramp up fundraising efforts in the next season so more students get the opportunity to get such an incredible hands-on experience.

“There are lifelong things that I hope students take with them because it will serve them well into the start of their careers and beyond,” Keyerleber said.