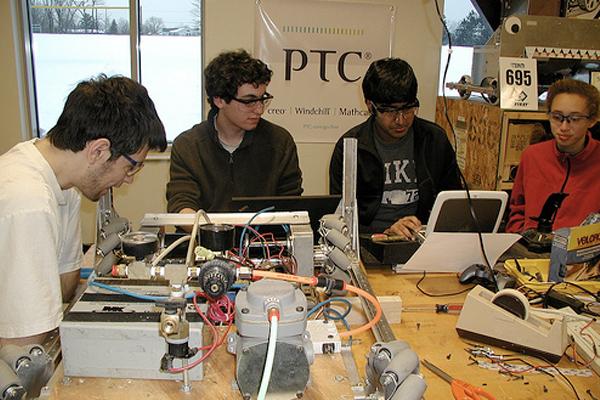

“We’re building a robot, and it’s going to be really cool,” said Junior Eric Novick.

Indeed, the robotics team has been building a robot to enter the Buckeye Regional competition this March. Over 50 teams participate, some of which come from out of state. The teams build robots to compete in a different game each year, and the top three teams go to nationals. This year, Beachwood’s robotics team will be known as team #695.

“Last year, we placed sixth out of the upper 50s. This year we hope to place in the top three so we can go to nationals,” said senior Tony Sapell, robotics club President.

This year, the game that the robots compete in is called “The Rebound Rumble.” The game is played between two alliances, each comprised of two teams. Alliances compete by scoring as many baskets as they can during each 2 min. 15 sec. match. The higher the hoop, the more points are scored. Alliances are awarded bonus points if they are balanced on bridges at the end of the match, but teams can be rewarded for collaboration also: if opposing alliances work together to balance on a certain bridge, those teams earn valuable seeding points.

“[The game is] sort of like basketball,” explained senior Tigran Askaryan.

Thus, team 695 has to design a robot that shoots soft balls into basketball hoops in order to score points. The robot must also be able to cross a bridge located in the center of the field and score bonus points by balancing on the bridge at the end of regulation time.

Robotics team members meet every day of the week, except on Sundays. They divide into teams that work on different aspects of the robot, such as the chassis team, program team, visual team and others. The robot is designed on Autocad Inventor before building really begins.

“We go into different groups to figure out the different aspects of the design first. We sketch them out and share them, vote on the top design and make prototypes to test,” said Sapell. “Based on how they work, we decide which one to go with and how we can improve.”

They don’t waste metal on prototypes, instead using wood. On the actual robot, they use aluminum for most parts, and steel for axles and certain bolts. The wheels are designed to move in any direction.

“We’ve been getting a few of our parts from a laser cutting company,” said sophomore Michael Halpern, referring to A-1 manufacturing. The pieces need to be precise, and can take a while to create. All the other pieces are made by the team members, and are modified when needed.

“We design it so that the parts can be built separately but assembled together,” said Sapell.

“I am impressed with the efforts these students are putting into this year’s Buckeye Regional,” said the team’s adviser Bob Davis. “They make a huge time commitment that involves about 20 hours a week for six weeks. I think the efforts are going to pay off at this year’s competition.”

At publication, the design of the robot is just about finished, with building already begun. Though the robot is currently unnamed, one team member wants to call it “The Scorpion.”

“I just want to thank all of our sponsors who make this possible,” said Davis. “Our sponsors include: Parker Hannifin, PTC, Ashton Technology Solutions, The Metal Store, A-1 Manufacturing, and Envision Radio Network. We would also like to thank our lunch sponsors including Subway at Beachwood Place, DiBella’s Subs at Harvard Park, Zeppe’s Pizza Bedford, Tree Country Bistro on Coventry and Chic-Fil-A Beachwood Place.”

![“My parents have always said that education is important. My parents are Chinese immigrants, I'm Chinese American, [and that's a] value that has always been ingrained in our community,” said Senior Lyndia Zheng, pictured with Tony Zheng](https://bcomber.org/wp-content/uploads/2025/10/DSC_4244.jpg)